28 years of experience in thequilt rolling machineindustry

Company Introduction

Information of Tian Yuan - A Leading quilt rolling machine Manufacturer

For nearly thirty years since its establishment, the company has always adhered to the core business philosophy of high quality, high efficiency, and high service quality, polishing products with exquisite craftsmanship and driving research and development with an innovative and enterprising spirit. With excellent product quality and a comprehensive service system, Tian Yuan has not only established a nationally renowned brand position in the domestic market, but also has products covering more than 30 provinces and cities across the country; Steadily stepping onto the international stage, exported to more than 100 countries and regions around the world, and won wide trust and praise from customers at home and abroad.

In the future, Tian Yuan will continue to adhere to its original intention, with technological innovation as the engine and high-quality service as the guarantee, committed to providing more competitive mechanical equipment solutions for the global home textile industry, and working together with partners to create a new future for the industry.

Our Team

TianYuan is a professional manufacturer of nonwoven equipment and home textile machinery, integrating research and development, production, and sales.

TianYuan’s products are characterized by high efficiency and low consumption, excellent performance, simple operation, convenient maintenance, few vulnerable parts, and beautiful appearance. The products can be widely used in the production of bedspreads, clothing, mattresses, pillow cores, duvet covers, and other bedding and nonwoven products.

The company provides customers with process design, technical consultation, and high-quality after-sales service. Adhering to the service tenet of “Dedicated to professional manufacturing and wholeheartedly serving you,” Tianyuan Machinery has become a model in the industry. We sincerely welcome your visit, guidance, and cooperation.

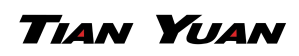

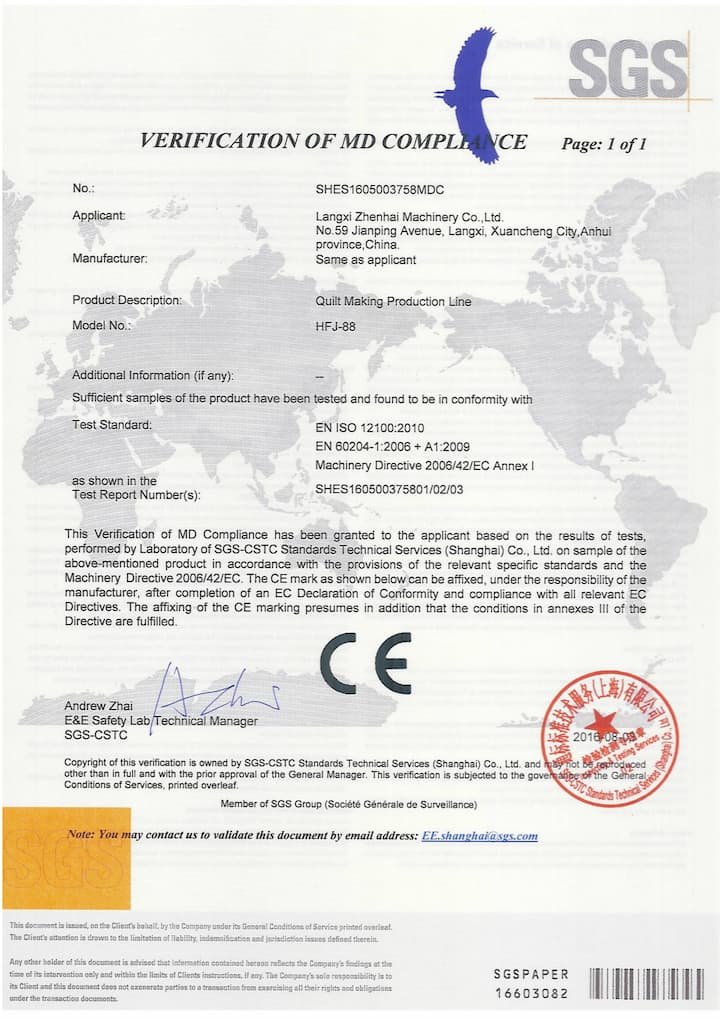

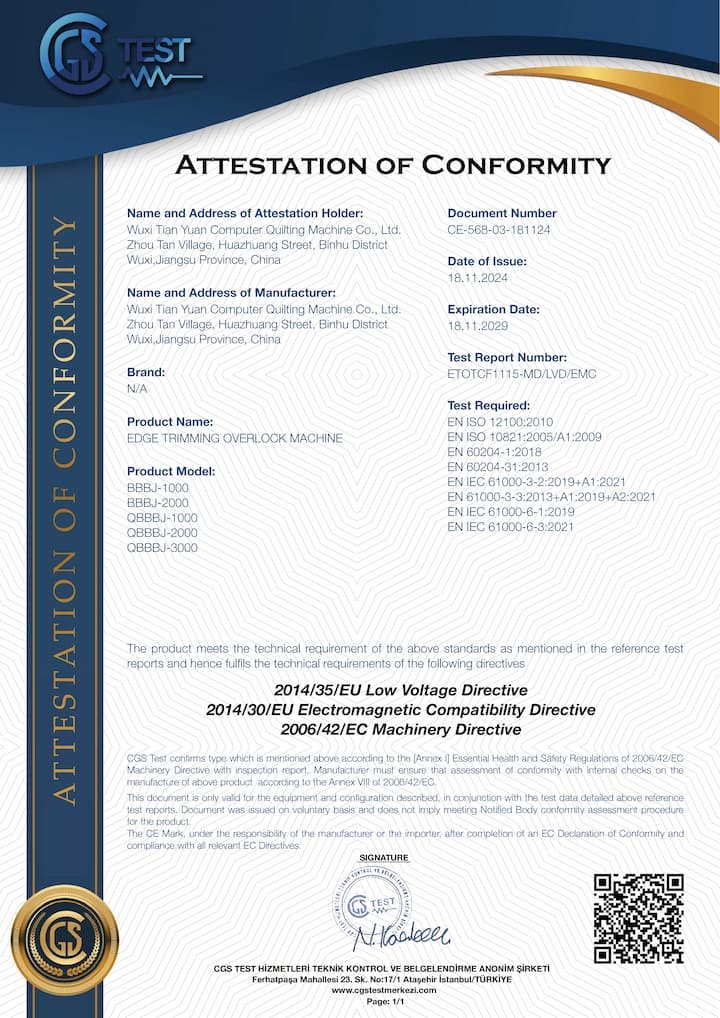

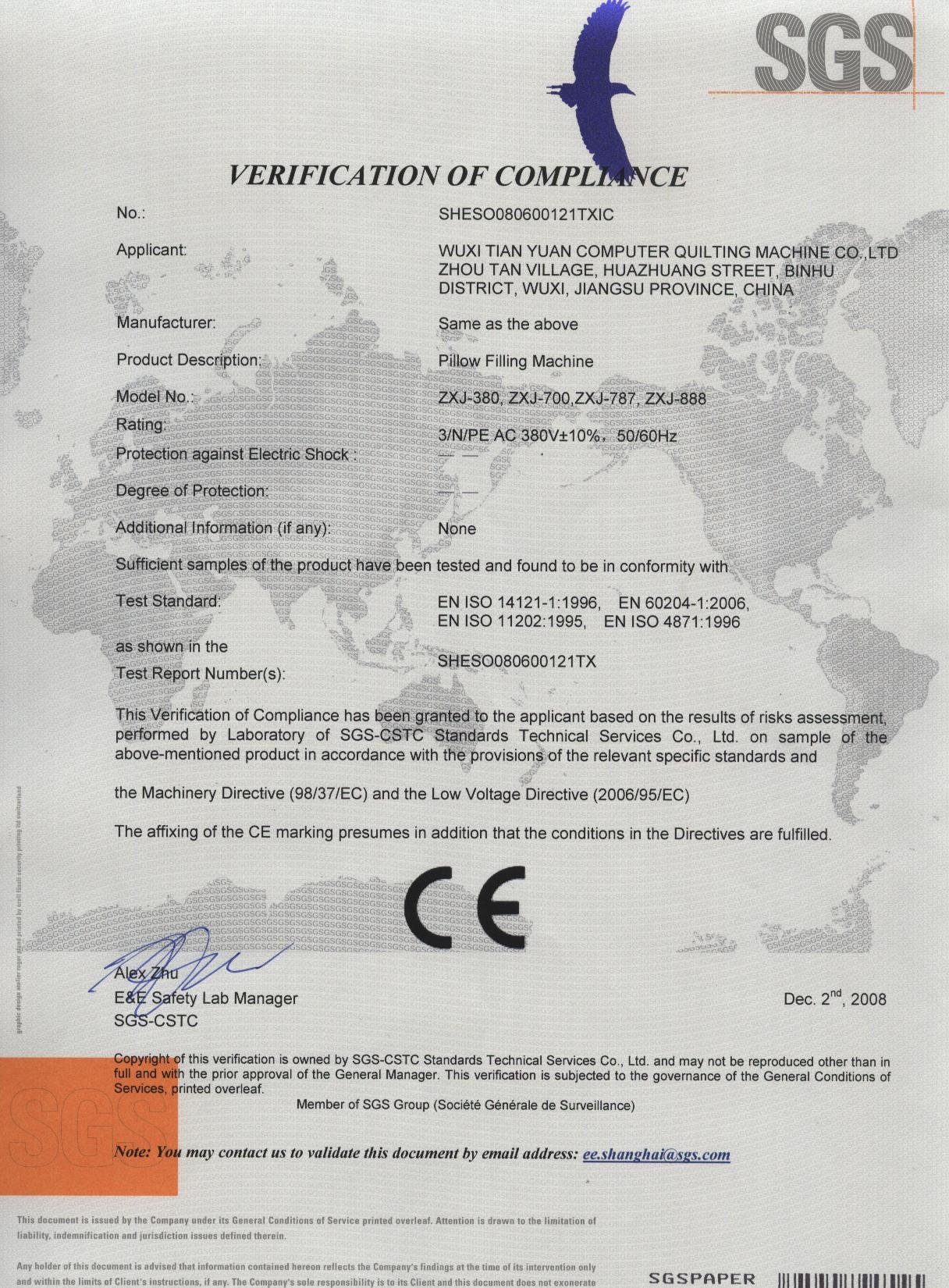

Our Production Qualifications

equipment

Intelligent, multifunctional, energy-saving and environmentally friendly.

assembly line

Small-batch production, customized orders, adapting to diverse assembly needs.

production line

Seamless process integration, quality controllable throughout the entire lifecycle.

Digital Optimization(生产细节)

Our new software solutions introduce innovative methods to increase machinery efficiency and optimize production cycles. By continuously tracking performance metrics and analyzing key performance indicators (KPIs) in real time, our systems identify bottlenecks and drive targeted improvements. With this data-driven approach every aspect of the production process is fine-tuned for maximum performance and reliability.

Our machines are continuously networked to give you as well as Brighi technicians direct access to the machines’ status and their real-time data. This dual-layer approach ensures that, alongside the preventive monitoring provided by our software, our expert staff can intervene promptly when needed.

Featured project(产品优势)

Our foam machines offer an all-around service: from the customized and discontinuous production of foam blocks, to its recycling by shredding and then rebonding. The goal is to obtain, in the first case, an innovative and less expensive filling material (such as shredded foam and spaghetti), and in the second, an environmentally friendly alternative to virgin foam blocks that is equally durable.

As regard to the pillow line, our technologies provide an optimized production process, including raw material processing, filling or stuffing, stitching, cover making, and packaging for a wide range of pillows and cushions. Each process can be fully automated or carried out with more manual technologies, depending on customer’s needs, since the modularity of the machines enables the implementation of the line over time.