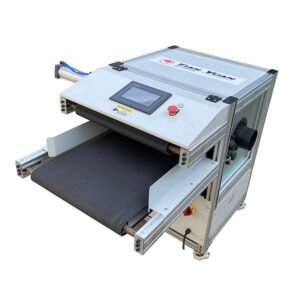

Compress Packing Machine

We guarantee a dedicated support line for rapid problem resolution. With a simple call, one of our qualified operators— available from both Italy and the United States—will promptly assist you. Our technicians can remotely monitor and diagnose the issue in real time. Additionally, we ensure fast and reliable supply of spare parts to minimize downtime and keep your operations running smoothly.

Roll Packing Machine

The success of any technological solution lies in the expertise of its operators. That’s why our well-versed technical team is dedicated to delivering complete and personalized training, both before and during the machine and software installation process. Our goal is to ensure optimal and safe operation of our systems, and a smooth startup of the line, reducing learning times.

Product List of Packing Machine

Product process and environment(产品工艺)

Raw material selection and pretreatment environment: Strict control at the source of quality

TianYuan takes raw material quality as the starting point of its core competitiveness and has established a full-chain quality control environment from global procurement to pre-treatment, laying a solid foundation for subsequent production.

In the raw material selection process, an independent raw material testing center has been established, covering an area of 200 square meters and equipped with 15 professional testing personnel. All raw materials entering the warehouse must pass 32 index tests. The mainstream raw materials are imported ABS plastic, food-grade PU and high-toughness PE, all of which comply with the dual environmental protection certifications of EU RoHS and REACH. For the high-end artificial tree series, biodegradable bio-based materials are specially selected to balance environmental friendliness and realistic texture. The color masterbatch is imported from Germany, ensuring color saturation and weather resistance. After testing, its outdoor UV aging resistance time can reach more than 10 years.

Core forming environment: Detailed replication supported by high-precision equipment

As a key link in the shaping of artificial plant forms, HRtrees’s forming workshop adopts a “high-end equipment + intelligent control” model to achieve precise replication of plant textures and forms. The replication accuracy of the branch and trunk patterns and leaf veins of its artificial trees exceeds 98%.

The workshop is equipped with 30 high-precision multi-material injection molding machines (the main model is the German KraussMaffei two-color injection molding machine), with clamping forces ranging from 920 to 3500kN, which can meet the molding requirements from small leaves (such as simulated ferns) to large simulated tree trunks (with diameters up to 50cm). For complex-structured products (such as artificial roses with flower buds), five-axis linkage injection molding technology is adopted to achieve simultaneous plasticizing and injection of multiple materials, with a one-time molding rate of 99.2%. All molds are independently developed by TianYuan. They are made of imported S136 die steel through CNC precision processing, with a surface roughness Ra≤0.8μm, ensuring that the surface of the formed products is smooth and free of burrs.

Surface treatment and coloring environment: Ultimate realistic visual presentation

To achieve the natural color and texture of artificial plants, TianYuan has created a multi-process integrated surface treatment workshop, combining meticulous manual operation with automated equipment to present the natural texture and color gradation of plants.

The workshop is divided into three functional areas: the screen printing area, the heat transfer printing area, and the manual coloring area. All of them are designed with constant temperature and humidity to avoid the influence of environmental factors on the coloring effect. The screen printing area is equipped with 18 fully automatic screen printing machines. For fine patterns such as leaf veins and petal textures, 200-mesh high-precision screen printing is adopted. The ink selected is environmentally friendly water-based acrylic color paste. After printing, it is quickly set by a UV curing machine, and the color adhesion reaches 5B level (tested by the grid method).

For large-scale complex textures such as artificial tree bark and large leaves, German imported heat transfer equipment is used. Through high temperature and pressure at 180-200℃, the patterns are transferred to the product surface. The texture clarity reaches 1200dpi, and a natural color gradient effect (such as the red and green transition of maple leaves) is achieved. The hand-coloring area is composed of 50 technicians with over 5 years of experience, who provide local fine coloring for high-end customized products such as artificial bonsai and artistic modeling artificial trees. All colored products must pass through a tunnel-type drying room to ensure the stability of the color and prevent it from peeling off.

Assembly shaping and clean environment: Structural stability and quality assurance

The assembly and shaping workshop of TianYuan ensures the stable structure and natural shape of the finished products through strict environmental control and process management, meeting the demands of the high-end market.

The cleanliness of the assembly workshop reaches the thousand-level standard. The workshop is equipped with 10 automated assembly production lines. Special tooling fixtures are designed for different product types. For example, the branch and trunk splicing of the simulated tree uses a fully automatic hot melt welding machine, and the connection strength is 30% higher than that of manual splicing. Small artificial plants (such as desktop potted plants) are assembled in a modular way. Workers complete the assembly of leaves, flower stems and flowerpots through an assembly line, with an average daily production capacity of 800 POTS per person.

The shaping process adopts differentiated solutions based on product types: Large simulation trees (such as 8-meter-tall simulation coconut trees) are placed in a dedicated high-temperature shaping furnace and shaped for 8 hours in an environment of 100-120℃ and 85% humidity, simulating natural growth forms. After shaping, they are cooled to room temperature by cold air, with a shape retention rate of over 95%. Flexible products (such as artificial vines and spider plants) adopt the process of “soaking with setting agent + cold air drying”. The setting agent is environmentally friendly polyurethane resin. After soaking, they are dried in a cold air room at 18℃ for 6 hours, and the setting effect can be maintained for more than 8 years. After assembly and finalization, the products need to go through three quality inspection procedures (appearance inspection, structural stability test, and weather resistance sampling test). Only after passing the inspection can they enter the storage stage.

Choose us

Your dream home deserves the best.(服务)

Professional team, high-quality building materials, perfect home. Work with experienced architects, designers and construction workers to build safe, beautiful and practical homes. Select high-quality building materials and pursue perfection in details to ensure the durability and comfort of the home. The satisfaction of you and your family is our goal. Let us work together to create a desirable home.

ONE-STOP SERVICE

From product consultation and selection to design andtechnical support to production process progress tosupply and delivery to installation and constructionsupport and after-sales service, we do everything wecan.

PRODUCT DIVERSITY

From product consultation and selection to design andtechnical support to production process progress tosupply and delivery to installation and constructionsupport and after-sales service, we do everything wecan.

SCHEME AND CASE

Our proud reference projects and implementation plansprovide you with endless inspiration and guidance.Whether it is a personal project or project construction,we can provide you with construction process experience.

ONE-STOP SERVICE

We export products to more than 120 countries aroundthe world. With our excellent reputation and quality ofproduct service, our customer base continues to expand.We are proud to have established close partnerships.

Ready to Choose Us?(引导下单)

Our image defined by services and products

Thank you for your interest in our products! We look forward to providing you with quality service and excellent products. If you are ready to choose us, please leave your name, phone number and email address, and our team will contact you immediately to provide you with detailed product information and quotation. Our image is defined by service and products, and we look forward to creating a satisfactory experience for you.